Boiler System Control

HeatNet 3.0 – an innovative, digital Boiler Management System that provides consistency and feedback through digital communication. By continuously monitoring several system characteristics, HeatNet 3.0 modulates boiler firing rates to maximize turndown ratios and maintain peak efficiency – no matter the load.

Maximizes System Efficiency

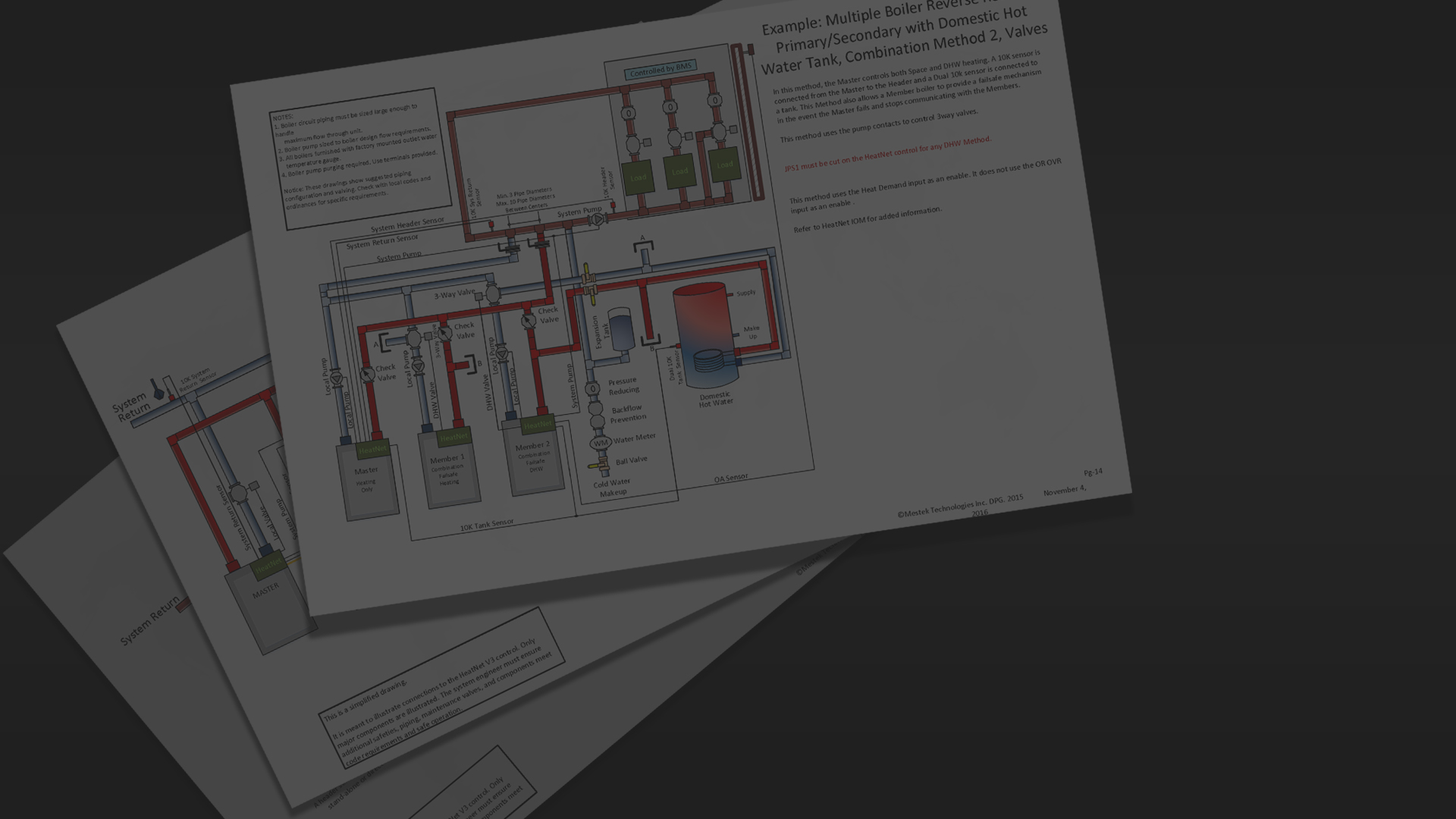

One boiler is designated as the Master and continuously communicates with all the Members on the network. The Master then dictates the operation of all the members. The result is a team of boilers that operate as a single high efficiency, high turndown boiler plant.

up to 16 boilers

Since all HeatNet controls can become a master and control the entire HeatNet boiler plant, costly third party, and wall-mounted control platforms can be eliminated. A HeatNet Master can operate a multi-boiler Master/Member network of up to 16 boilers, even incorporating a mixture of condensing boilers and non-condensing boilers to maximize system efficiency.

Easy to Use

HeatNet boilers use a 7” color display, which is easy to read. The touch screen allows for easy menu navigation and displays complete system status to verify operation and simplify troubleshooting.

Online Monitoring

HeatNet Online is a web-based monitoring program that allows visual boiler feedback from anywhere through an easy to read dashboard. View boiler set points, service logs and system issues from your office computer, tablet or cell phone. HeatNet Online sends email text alerts for out of specification operation allowing for proactive responses to potentially harmful situations. Eliminate no heat conditions

Application Flexibility

HeatNet can control both space heating and DHW boiler loops simultaneously, match the system load by intelligently staging different size boilers, or reduce system cost by implementing condensing and non condensing boilers in a single system. Two system pumps are supported for rotation and redundancy, the system pump and local pump can be varied based on input, and the number of boilers that are allowed to fire can be limited based on system water flow. Power open/spring return, power close/spring open, and power open/power close valves are supported. Individual and common system combustion air dampers are supported, and a lead boiler can also be selected to create draft for common vent installations.